GREEN!

The Problem We have Solved

Every time driving on a highway near a semi-trailer truck, you are taking a considerable amount of risk, as crashes involving cars and semi-trailer trucks are very dangerous. People travelling in smaller passenger cars are vulnerable and statistics confirm that most deaths in large truck crashes are occupants of the smaller vehicles. Trucks often weigh 20-30 times as much as an average passenger car weighs. Also, trucks are taller with greater ground clearance, which can result in smaller vehicles under-riding trucks in crashes. High centre of gravity is also an important factor in lateral instability of a semi trailer truck.

According to the National Highway Safety Administration, a total of 4,119 people died in large truck crashes in 2019. Sixteen percent of these deaths were truck occupants, 67 percent were occupants of cars and other passenger vehicles, and 15 percent were pedestrians, bicyclists or motorcyclists. The number of people who died in large truck crashes was 31 percent higher in 2019 than in 2009, when it was the lowest it has been since the collection of fatal crash data began in 1975. The number of truck occupants who died was 51 percent higher than in 2009. For more information on highway collision fatality statistics please visit:

https://www.iihs.org/topics/fatality-statistics/detail/large-trucks

Our Solution - WARDEN

WARDEN is an innovative, inexpensive, non-invasive, and simple solution, that eliminates / minimizes Jackknifing.

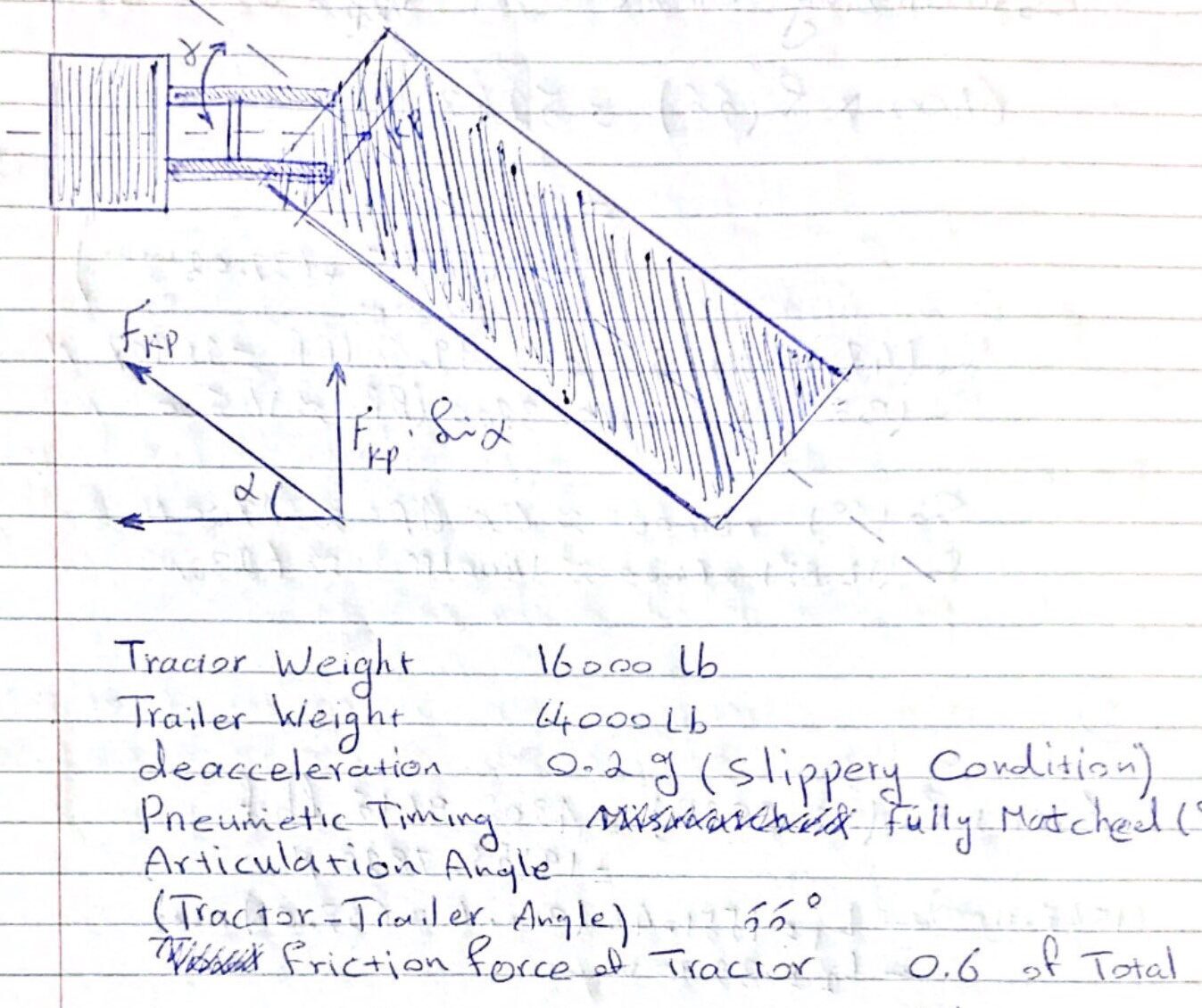

In the past both governmental organizations and academic institutions have conducted exhaustive research and study on lateral stability analysis of articulated vehicles, from which we learned a great deal. Here at PlusTime we took the study one step further with the purpose of utilizing the results to produce a solution that will eliminate jackknifing and make our roads safer. more Our Approach – Most of the commercial transport trucks seen on highways are of dry-van kind. In this combination a two axel 16m (53ft) trailer is hitched to a towing vehicle. Once fully loaded, these vehicles weigh 36,300Kg (80,000 pounds). Whereas a typical mid-sized passenger car weighs about 1800Kg (4000 pounds). 80,000 pounds by no means is the maximum weight of a laden transport truck that we see on the roads. The more axle a trailer has the more weight it can haul. The highest maximum allowed speed on our highways is 100 km/h. This is about 5 km/h less than maximum speed that a typical transport truck can travel. The fact that more mile a driver covers the more money he makes, as well as the rushed delivery schedule imposed by dispatches, compel drivers to drive as fast as they can. That is 105 km/h, for most of the time (about the speed of much smaller passenger cars). To slow down a moving vehicle or bring it to a full stop, the brake system of the vehicle converts its kinetic energy into thermal energy, through pressing brake pads against a heat absorbing component (disk/drum). The created heat is then dissipated into air, allowing drum to cool down for further heat absorption. The kinetic energy of a mass M travelling at the velocity of V is calculated as: E.K = (1/2) * M * V ^ 2 The direct correlation between the mass and kinetic energy in this equation means that the brake system of transport truck must be capable of handling 20-times more thermal energy than that of a passenger car. This underlines the importance of regular inspection and appropriate maintenance of brake system in transport trucks. Lateral Stability of Articulated Vehicles Stopping Distance – Total stopping distance is the distance that vehicle travels from the time that driver sees a hazard and presses on the brake until the vehicle stops. According to Federal Motor Carrier Safety Administration (FMCSA) a fully loaded tractor-trailer weighing 80,000 pounds traveling under ideal conditions at a speed of 100 kilometres per hour will take 160 meters to stop (almost the length of two football fields). Total stopping distance is made up of three parts: Perception Distance – The distance a vehicle travels while a driver is identifying, predicting and deciding to slow down for a hazard. Reaction Time – The time it takes for a driver to execute a decision once a danger is recognized. The distance your vehicle travels while you react is called a reaction distance. Braking Distance – The distance a vehicle travels from the time a driver begins pressing on the brake pedal until the vehicle comes to a stop. For further details on stopping distance please visit https://trucksmart.udot.utah.gov Pneumatic application Time – defined as the time required for the brake chambers to reach a relatively high-pressure level after the driver applies the brake control, effects vehicle stopping distance. The sooner that air pressure builds in the brake chambers, the sooner the vehicle will be able to reach its maximum deceleration rate, and the shorter the vehicle’s stopping distance. In addition to its impact on stopping distance, pneumatic application time of each unit in articulated vehicles during steady state braking, also affects the coupling forces between the units. This is a compressive force on fifth wheel of the towing unit, which results in bending moment on kingpin. Meaning, If the towing unit has considerably shorter pneumatic application time than that of its trailer, a forward compressive force will be exerted on the fifth wheel of the towing unit. On the other hand, in articulated vehicles with synched (or trailer with shorter) pneumatic application time, the force applied on the fifth wheel can be (but not always) considerably smaller or possibly negative (trailer pulling the trailer backward). For zero compressive force on fifth wheel, other conditions must exist, as it is explained below. If there exist a coupling force in an articulated vehicle and the articulation angle θ (the angle between towing vehicle and its trailer) is not zero, the F.Sin(θ) component of compressive force will result in a moment about the centre of gravity of the towing vehicle that can destabilize the vehicle. Therefor to maximize the lateral stability of an articulated vehicle, the compressive force on the fifth wheel of the towing unit must be minimized. Also, if ratio of brake force of each unit to total brake force of the rig is not the same as ratio of mass of that unit to total mass then there will be a compressive force on the fifth wheel of towing vehicle. Meaning if (braking force of a unit / total braking force of rig) not equal to (mass of that unit / total mass of vehicle), then there will be compressive force on the fifth wheel of the towing vehicle. Load distribution – Once dolly legs of a laden trailer in an articulated vehicle are lifted, drive axel of the towing vehicle will support a large portion of the trailer weight, without which brake force of the trailer wheels would not be able to support total load (the coefficient of the friction between the trailer tire and road remain the same, however the vertical pressing force is less on trailer wheels now, since a significant portion of it is supported by drive axel of the towing vehicle). This necessitates brakes of the towing vehicle to be sized in a way that it can provide brake for the portion of the trailer load that it supports. This means that during steady state braking the compressive force on the fifth wheel of the towing vehicle will always exist regardless of how accurately pneumatic application timing of the towing vehicle and its towed trailer are synchronized, except for the combination in which the trailer is empty or the brake force ratio of the unit is the same as mass ratio of that unit. In instances where excessive compressive force is inevitable, the operator must try to reduce the articulation angle to the minimum possible (if not zero), to minimize created moment on the towing truck (around it centre of gravity), to maximize the stability of the vehicle. Because compressive force acting through centre of gravity of the towing vehicle, during steady state braking, will not result in a moment). There are a few special cases to consider. Brakes are sized for the worst-case scenario, in which trailer is assumed to be fully loaded. When the trailer is empty, the portion of the trailer weight supported by the drive axel of the towing unit is minimal, in which case if the compressive force on the fifth wheel of the towing unit during the steady state brake exists, it mainly will be the result of mismatched pneumatic application time of the two units. With properly adjusted pneumatic application timing the compressive force can be zero or negative because the created brake force will be greater than force that mass of the empty trailer can exert. Also, if the braking force is proportioned to mass distribution among the units, the compressive force on the fifth wheel of the towing unit can be zero. Again, the assumption is that the pneumatic application timing is properly adjusted among the units. On the other hand, lateral instability of the articulated vehicles can be result of not only disproportionate brake force ratio among the units but also imbalanced distribution of weigh among them. Performance of brakes directly effect magnitude of the compressive force on the fifth wheel of the towing vehicle and consequently the lateral stability of the whole rig. Forward compressive force on the fifth wheel of the towing vehicle has a backward reaction shearing force causing bending moment on the kingpin of the trailer, which essentially is a cantilever beam. Through mathematical models, simulation applications, and full-scale vehicle tests the effect of pneumatic application timing on kingpin shear force can be quantified. It is noteworthy to mention that analysis of the shearing force on kingpin during application of brake is different than that of the compact force, applied by the fifth wheel during coupling (in coupling tractor moves backwards until the kingpin on the semi-trailer interlocks with fifth wheel affixed on the tractor). Due to IP considerations, we are unable to further discuss our approach to solving the Jackknifing here. Please feel free to contact us for any enquiry in this regard.

For the foreseeable future and beyond we will see trucks travelling on our roads in numbers. With millions of people on the roads everyday, road safety must be of the highest priority for everybody involved in transportation industry.

THE IMAGE ABOVE IS FORM PUBLIC DOMAIN (WE HAVE DOWNLOADED IT FROM THE INTERNET).

OWNER OF THIS IMAGE, WE THANK YOU. HOWEVER, PLEASE INFORM US TO REMOVE IT IF YOU WISH SO. WE WILL REMOVE IT INSTANTLY.

416-285-1111

Get Involved

We are actively looking for local businesses partners to expand our presence in new areas. For more info please send us an email at:

enquiries@plustime.ca

or call us at:

416-286-1111

- We have tied success of our business to that of our associates’.

- We strive to establish mutually profitable business ties with local business entities to produce and offer our products.

- We respond to calls of our business associates’ to help them to resolve challenges they may face and support our customers’ to meet their needs.

Made In Canada

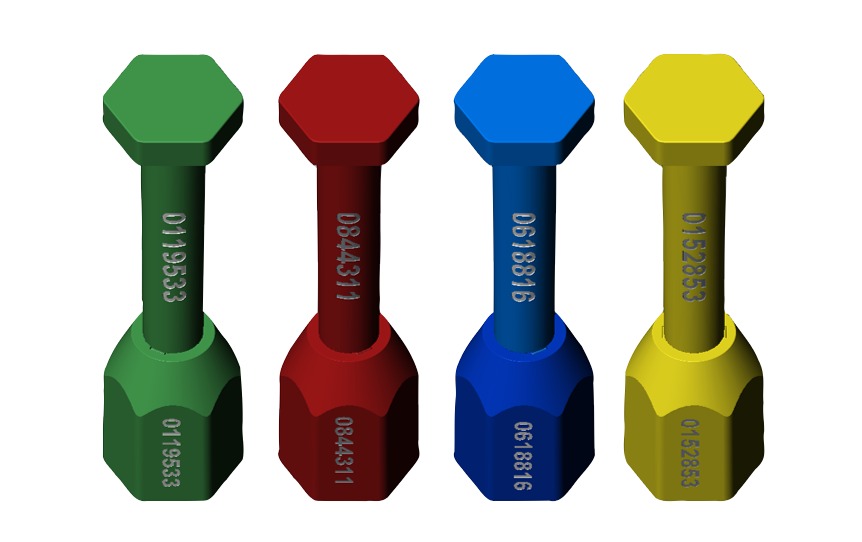

In an attempt to bring manufacturing production back home, as the first step, we have redesigned one of the most used parts in logistics industry. We have realigned design parameters of the bolt-seal with principles of DFMA to an extent that it can be produced in small size production settings. read more

We Need Your Support In This Battle.

Thank You