BUSINESS MODEL

Made in canada

COVID-19 pandemic underlined the urgency and importance of re-shoring manufacturing production. We have inherited an economic system, in which production of even the simplest of goods here at home is unattainable. So much so that we continued importing the blue colour disposable facial masks from china, even after the video clips of chinese factory workers cleaning their shoes with the exact same blue masks went viral.

Promotion of goods made here at home is one of our fundamental objectives. However, the economic system that we have inherited presents an immense set of challenges for manufactures here at home.

High production cost here at home is regularly associated with the high labour cost, which is partially (but not entirely) true, as the “high labour cost” is merely an effect of other main root causes, discussion of which is out of scope of this article.

The ability to compete with lower priced off-shore made knock off versions of our (Canadian) designs, calls for significant overhaul of traditional production practices here at home. This is specially true for price sensitive products, which nowadays cover a vast majority of product spectrum.

Development of fully or partially mechanized production settings, which has been utilized by the major players in auto industry, has been an effective strategy for production of domestic cars. However, for products with a smaller market segment, automation may not be feasible if not impractical. Having said that, as Aristotle the ancient Greek philosopher said, infinite number of infinitesimally small quantities is an infinitely high quality. Simply put, ignoring these small quantities has proven costly, even for the largest economies.

Introduction of easy to operate fully or semi automated desktop injection molding machines, laser cutters, 3D printers has presented a unique opportunity to produce a wide variety of plastic parts in small garage size production settings, while complying with required industry standards.

logically, production process of a part in a small garage sized production cell should be drastically different than that of a big fully equipped manufacturing facility. Depending upon the complexity of the task, and to pursue economics of scale, in large manufacturing facilities skills, activities, processes, products, and customers are grouped and departmentalized. On the other hand, in a small garage sized production cells all of the task is performed by one or a small number of people.

To facilitate production of parts in small production settings, in addition to the production process, it maybe necessary to modify geometric characteristics and material properties of the design elements, assuming its functional objectives are not compromised.

SOME OF THE PICTURES ON THIS SITE ARE FORM PUBLIC DOMAIN (WE HAVE DOWNLOADED THEM FROM THE INTERNET).

OWNERS OF THE PICTURES, PLEASE INFORM US TO REMOVE THEM, IF YOU WISH SO.

416-285-1111

Profit Now. Last Long.

We are actively looking for local businesses partners in US and Canada to expand our presence in new areas. For more info please send us an email at:

enquiries@plustime.ca

or call us at:

416-286-1111

- We have tied success of our business to that of our associates’.

- We strive to establish mutually profitable business ties with local business entities to produce and offer our products.

- We respond to calls of our business associates’ to help them to resolve challenges they may face and support our customers’ to meet their needs.

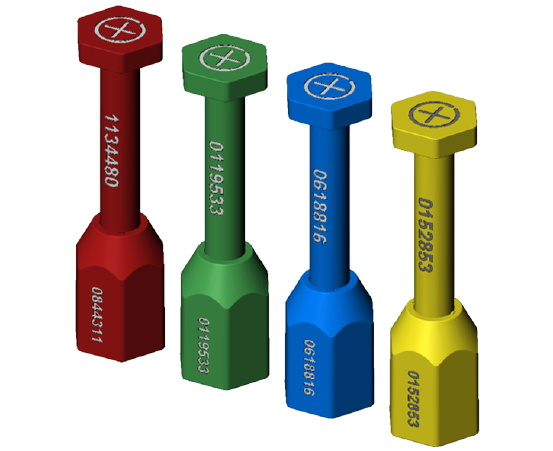

Bolt Security seal

In an attempt to make production of Bolt Security Seal possible in small production settings, we have modified its design elements. Implemented changes have not reduced or otherwise limited its functionality.

Thank You For Your Support

We Need Your Support In This Battle

Thank You